All water-based underfloor heating (also known as UFH) systems comprise a series of pipes laid beneath the surface of your floor. Manifold underfloor heating is the central distribution point for all the floor heating pipes. Warm water is streamed through these pipes when the system is switched on, creating an even spread of heat across the floor surface above.

‘The manifold has a series of electronic actuators that are linked to each individual room thermostat, giving you control over each room, heating times and temperature,’ explains Tom Edmunds, general manager at Wunda Group.

As well as connecting the underfloor heating pipework to the heat source itself (ie boiler, heat pump etc), it is the manifold’s job to control the flow rate of water through the pipes, ensuring the warm water is distributed evenly. The manifold also plays an important role in regulating the temperature and pressure of your system.

There’s a selection of styles and sizes to choose from – your heating engineer will be able to provide advice on which one is right for your setup. Getting the installation of the manifold right is crucial to the performance of your underfloor heating, so fitting it is always a job that’s best left to a professional.

Here, we explain everything you need to know about manifold underfloor heating, from where best to position it to the upkeep that’s required.

What is manifold underfloor heating?

Image credit: Volodymyr Vorona/Alamy Stock Photo

The manifold forms the central hub of your UFH system, featuring a series of ports that connect to each loop of pipework within your setup. To understand how the manifold works, it’s important to understand how the pipework in your system is laid first.

The pipework through which warm water flows is laid in snake-like loops known as circuits. Typically, there will be one circuit per room, or perhaps multiple circuits in a large, open-plan area. Each circuit connects back into a single port within the manifold, allowing independent control of the temperature in each zone.

Your manifold controls and regulates each of the circuit loops concurrently. Allowing you to run the heating at different temperatures in different areas using the thermostats placed in each of the rooms where you have underfloor heating. Your ability to regulate the temperature in each room allows for a more efficient use of heat, so you’re not wasting energy warming rooms that you spend less time in.

‘The manifold is the only place in the UFH system where you’ll find joints,’ says Matt Densham at Robbens. ‘Having the manifold ensures there are no joints in the UFH pipes that run under the floor. This ensures there aren’t any leaks, and also allows the UFH system to be zoned, improving energy efficiency further.’

What types of manifold are there?

The size and type of device that’s required for your unique underfloor heating setup will depend on the scale of the project, the type of UFH system you’re using and the number of rooms you’re installing it in.

For instance, if you’re fitting UFH in an open-plan kitchen-diner, living room, den, home office and WC, you’ll require a larger manifold with more ports than if you are only installing in a couple of rooms. The floor and underfloor heating type (screeded or non-screeded) need to be taken into consideration, too.

‘There are several types of manifolds made from brass, or even plastic,’ says Tom Edmunds at Wunda Group. ‘Stainless steel is the most hard wearing for a long, hassle-free life.’

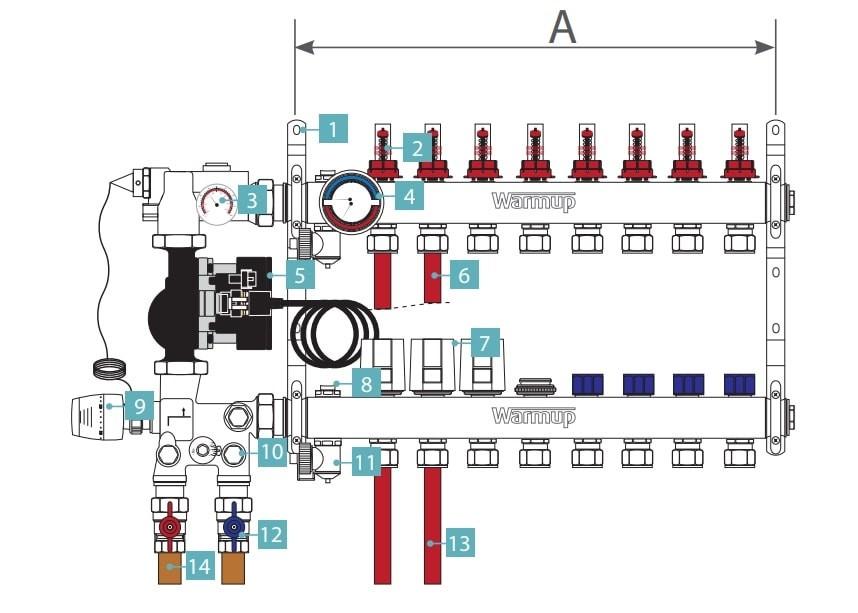

As the manifold is responsible for controlling the pressure the water flows at, as well as the temperature, it comprises several key components. For example, there will either be a manual or automatic air vent used to remove air from the UFH system.

There will also be drain valves for the initial filling and draining of the pipes. Flow gauges are another key part of the device, responsible for monitoring the correct flow rate and temperature of water sent to each zone (this will be determined by the individual heat requirements for each space).

The wiring centre of the manifold is another key component. ‘This monitors the electrical aspect of your setup by establishing a link between the manifold and the boiler and thermostat,’ says Sarah Wazir, a marketing executive at Warmup. ‘Usually linked to the actuators and thermostats, this central hub manages the running of your heating system.’ This is quite different to how electric underfloor heating works.

How does an underfloor heating manifold work?

It’s helpful to start with the thermostats that are installed in each of the rooms where you have underfloor heating. Each of these will be programmed in to warm up to your desired heat, at the desired time. ‘When the thermostat senses a need for heat, it will signal the heat source (ie boiler) to supply warm water to the manifold,’ says Tom Edmunds.

‘The thermostat will also signal the manifold to open to the loops of pipe connected to that thermostat and switch on the pup to circulate warm water around the loops of pipe that are calling for heat.’

Once the required temperature has been reached, the thermostat will signal the manifold to close the pipe loops, stopping the circulation of water. ‘If all rooms have reached the desired temperature, the heat source will also receive a signal to stop supplying heated water,’ says Tom Edmunds.

Image credit: Future PLC/ Adam Carter

Where should an underfloor heating manifold be placed?

Positioning the manifold correctly is vital to ensure the efficient running of your UFH system. ‘The best place is central to the heating zones,’ says Sarah Wazir. ‘By installing it centrally, you’ll be able to keep pipe lengths to a minimum. Making sure that the flow of warm water reaches the area to be heated evenly and efficiently.’

It’s useful to have the manifold somewhere accessible, so it’s easy to get to for maintenance, but not on display. A cupboard under the stairs might do the trick, or in a cloak room cupboard. Some UFH suppliers provide slimline cabinets manufactured specifically to accommodate the manifold and the associated pipework.

How do I install an underfloor heating manifold?

A water-based heating system should always be fitted by a professional heating engineer or plumber who will be able to advise on underfloor heating costs. They will start by checking the design plans to see which port serves each specific loop within your system.

Next, the pipework will be laid out, using the most efficient route between the centrally-located manifold and the zone itself. Each pipe will follow the came route back to the manifold, connecting into the return bar. Once all the circuits have been connected to the manifold, the system can be pressure tested. This step should always be carried out before the screed or self levelling compound is laid.

How do you balance an underfloor heating manifold?

Image credit: Robbens

‘Balancing’ your underfloor heating system is simply the process of ensuring the right volume of water is being distributed across the system. Meaning the heat is spread evenly throughout. Large volumes of water typically flow towards shorter pipe circuits, sometimes leaving longer runs of pipework with a lesser flow. This is why it’s so important to make sure the manifold is centrally located – to keep the pipe running as even as possible.

To establish optimum efficiency, your installer will create resistance within short pipe circuits and less resistance in long pipe circuits, ensuring that each of the loops has the correct volume of water flowing through. This is done via the process of balancing, via a manual adjustment of the flow meters on your manifold.

Video Of The Week

All you need to do is open and close these meters until the desired flow is achieved – this figure will be indicated on your UFH design plans. If you’re unsure, ask your installer to show you how to do this at the point when he or she fits the system. It’s a quick job that’ll only take a couple of minutes but makes a huge difference to the overall efficiency of your system.